Overview

ELEGANT + COMPACT

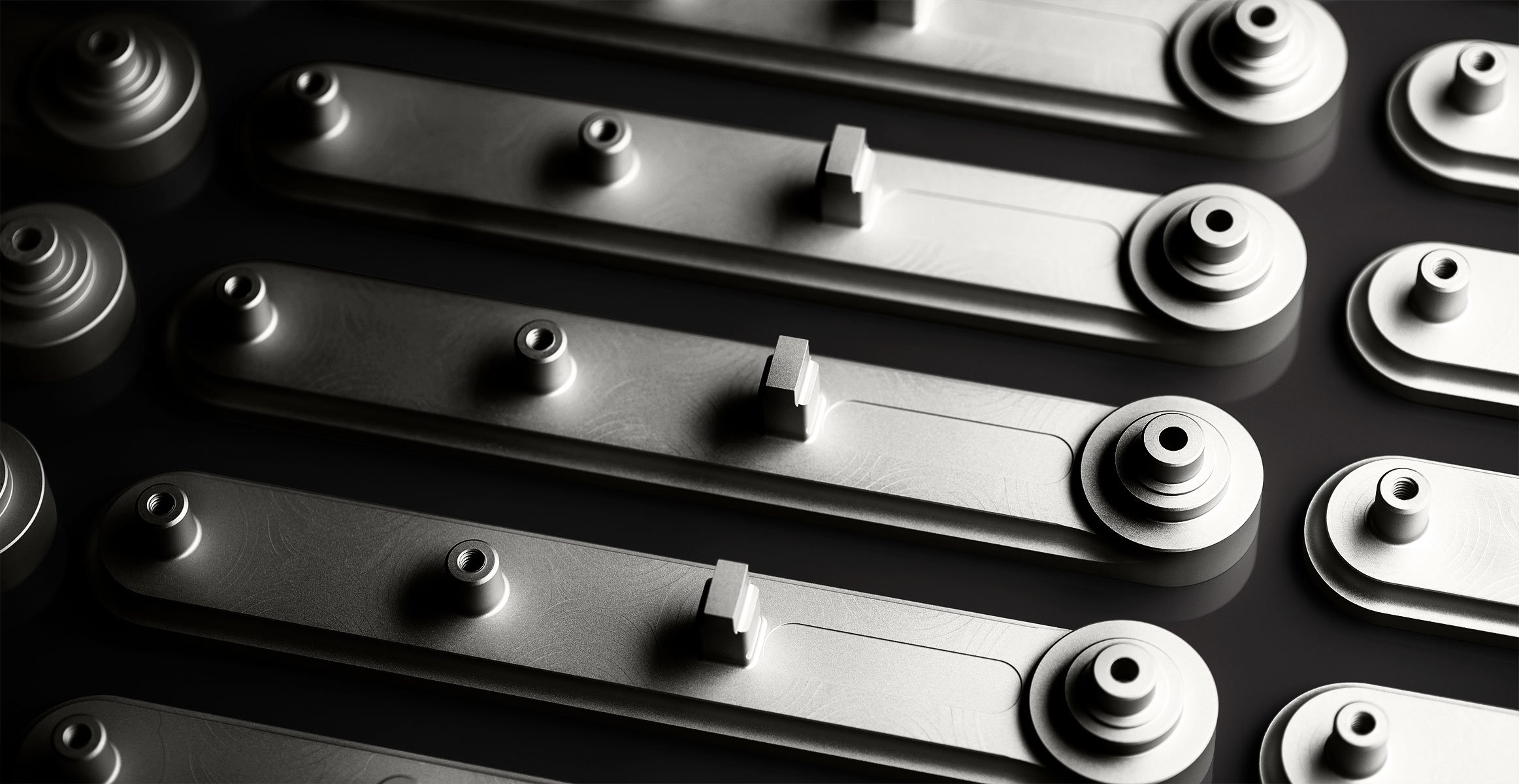

Now Krownlab's superior design and manufacturing are in reach of any project. The Loki system delivers industry-leading performance and beauty at an accessible price point. We went back to the drawing board to design a simplified trolley and wheel, along with a new finishing process, that works with our unique 2-part track. All the fasteners are concealed and the key features providing quick and precise installation are all there. Your project deserves nothing less.

200 LB. MAX CAPACITY

With our extensive experience in residential and commercial projects across the globe, we've found that most doors weigh less than 200 lbs. In designing Loki, we decided to cater to this majority. Simply put, the engineering required to operate a 400 lb. door isn't always needed.

FOR WOOD AND GLASS DOORS

Our versatile hardware systems, Loki included, will work with a wide range of door materials. Wood, glass, metal, plastics such as 3Form, and a combination of materials are all compatible with our systems. If you have a design challenge, we are ready to partner on a solution.

SUPERIOR QUALITY

The Loki sliding door system has been designed with high-use projects in mind. Our industry-leading 10-year warranty is backed by rigorous testing: our lab has wear-tested to over 2 million open-and-close cycles, and counting. Loki is constructed from anodized high-grade aluminum—a premium metal that translates to unparalleled product longevity.

THE TRU-LEVEL™ SYSTEM - COMPLETE FIELD ADJUSTABILITY

With the Loki sliding door hardware system, installers will have perfect installations in less time. To function properly, any sliding door track system needs to be mounted absolutely level. Drilling a half-dozen holes in a flawless line is not easy. But hidden inside Loki's track is the Tru-Level System™, giving 1/4” of out-of-level adjustability at each mounting point, during or after installation.

DESIGN FOR ALL

Loki is compatible with ADA pull force requirements on door panels of almost any size and material. And it does so without compromising effortless movement.

ORDER ONLINE

Looking for a quote? Ready to buy? Go to our product configuration tool.

Our step-by-step product builder ensures you'll get the right configuration for your installation. And don’t worry about making the wrong selection. We review every order to make sure our hardware works with your project. Need further assistance? Just give us a call: 503 292 6998. We're here to help.

Mounting Systems

-

Top Mount

SELECTED -

Face Mount

SELECTED -

Glass Mount

SELECTED

ADJUSTABLE CLEARANCE

Unlike our surface-mounted products, which reference off the face of a door panel, Top Mount can be biased either toward the front or back of the panel, allowing you to get your door panel precisely the desired distance away from the wall. Because of this adjustability, we recommend Top Mount for installations involving door trim, molding, or base board.

FOR THICK PANELS

Working with a particularly thick door panel? Top Mount is often the best option. If your panel is 1-3/8" to 3", or up to 2-1/2" with typical wall trim, Top Mount has you covered (for thinner panels, contact Krownlab Support). By biasing trolleys toward the back of the panel, the only upper limit to your panel thickness is the material you find. So take that slab of reclaimed lumber, and go forth with confidence.

FOR PANELS 1-1/4" to 2-3/8"

Face Mount supports panels from 1-1/4" to 2-3/8", or up to 1-3/4" with typical wall trim. For thicker door panels or thicker base board, use Loki Top Mount. Not sure exactly how thick your panel will be? We include four lengths of panel mounting screws so that you don't have to worry. For panels outside this range, contact Krownlab Support.

FOR GLASS PANELS 3/8" TO 1/2"

Although 1/2" is the most common glass thickness we see, our Glass hardware is compatible with 3/8" to 1/2" thick panels. (Prefer the metric system? Our Glass Mount hardware systems are compatible with 10mm to 12 mm glass) Glass systems include a 2" long stainless steel bottom guide specific to the thickness of your panel.

Finishes

-

Black StainlessSELECTED

Black StainlessSELECTED -

Brushed StainlessSELECTED

Brushed StainlessSELECTED

BLACK STAINLESS

Premium black metallic finish with a fine brushed material surface texture. Often referred to as a No. 4 directional grain, this fine texture is smooth to the touch and adds sophistication to the appearance. This highly durable finish is either achieved through a proprietary two-step electrolytic anodizing, or a black oxide process. Unlike the commonly used paint, plating, and powder coat processes, this finish will never crack, chip, or flake.

BRUSHED STAINLESS

This premium directional finish is consistently our most popular. Parts are precisely textured with a fine linear or circular grain. Often referred to as a No. 4 directional finish, the fine linear graining is smooth to the touch and adds a sophisticated texture to the product. For similar finishes offered on other Krownlab products, consider Stainless Steel.

Additional Products

-

Oden

- Sliding barn door hardware

- For wood and glass panels

- 400 lb. std weight capacity

- Brushed and Black Stainless

-

Asta Recessed Pull

- Recessed linear door pull

- Single and double sided

- Multiple lengths available

- Brushed and black finishes

-

Kor Ladder Pull

- For hinged and sliding doors

- For wood and glass panels

- Available in 24”, 36” and 48"

- Stainless Steel and Black Stainless

-

Inger Linear Pull

- Protruding linear door pull

- For wood and glass panels

- Multiple lengths available

- Brushed and Black Stainless